In the fast-paced world of industrial automation, Hydraulic Cylinders play a pivotal role in delivering the force, precision, and reliability needed to keep machines running efficiently. Whether it’s in manufacturing plants, construction equipment, or heavy-duty industrial systems, these devices transform hydraulic energy into linear mechanical motion, powering countless automated processes.

In this blog, we’ll explore what makes hydraulic cylinders so crucial in industrial automation, the advantages they offer, the different types such as Double Acting Hydraulic Cylinders, and how to choose the right Hydraulic Cylinder Manufacturer for your needs.

Understanding Hydraulic Cylinders

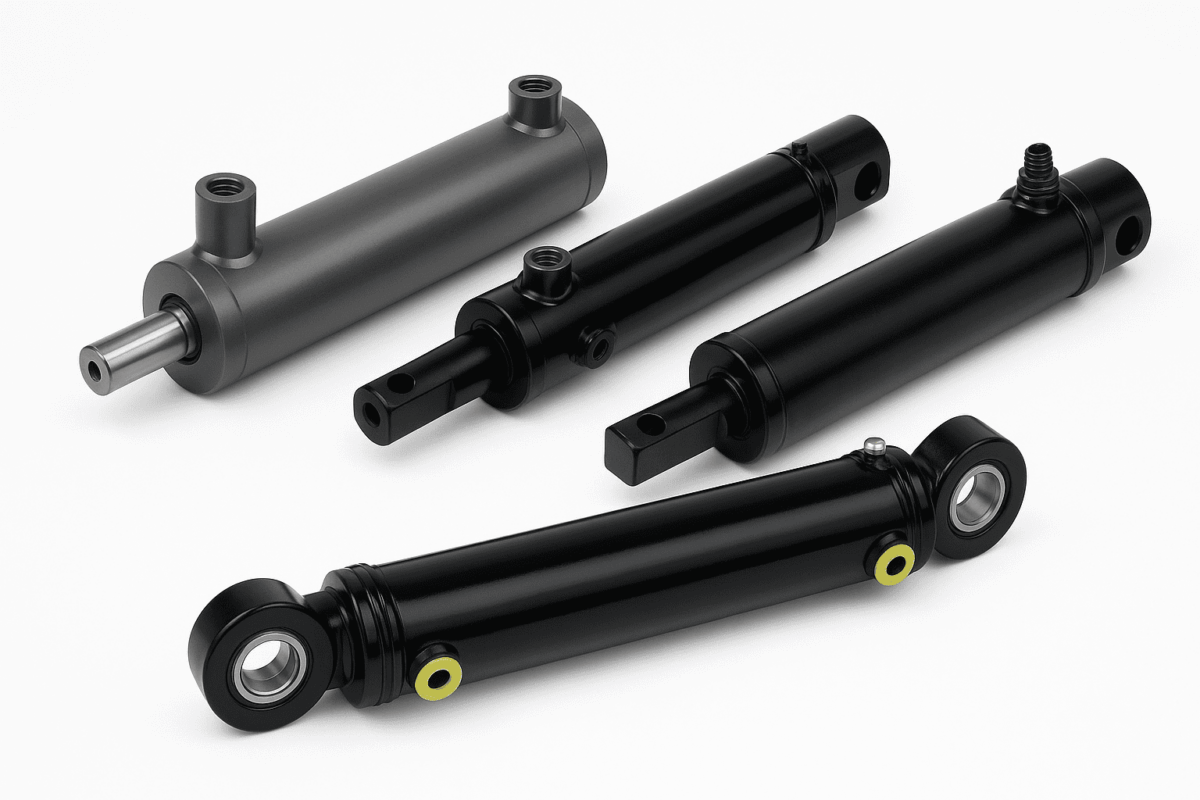

A hydraulic cylinder is a mechanical actuator that uses pressurized hydraulic fluid to produce linear force and motion. The system typically includes a cylindrical barrel, piston, piston rod, seals, and hydraulic fluid. When pressurized oil enters the cylinder, it pushes the piston, creating movement.

Key Functions in Automation:

- Lifting and lowering heavy loads

- Precise positioning of machinery components

- Controlling industrial presses and clamps

- Enabling repetitive, high-force tasks with minimal human input

Why Hydraulic Cylinders Are Indispensable in Automation

Industrial automation demands a combination of high force, accuracy, and durability, which is exactly what hydraulic cylinders offer. Here’s why they are irreplaceable in modern automated systems:

1. High Power-to-Size Ratio

Hydraulic cylinders can produce tremendous force in a relatively small size. This allows them to operate in compact spaces while delivering the power required for heavy-duty industrial applications.

2. Smooth and Precise Motion

Automation often requires exact control of movement. Hydraulic cylinders allow for precise stroke adjustments, ensuring consistent and repeatable motion — critical in manufacturing and assembly lines.

3. Reliability in Harsh Environments

From high-temperature steel plants to dusty mining operations, hydraulic cylinders can operate reliably in extreme conditions, thanks to their robust construction and high-quality sealing systems.

4. Cost-Effective Over the Long Term

When maintained properly, hydraulic cylinders offer long service life, reducing downtime and replacement costs.

Double Acting Hydraulic Cylinders in Automation

While there are several types of hydraulic cylinders, Double Acting Hydraulic Cylinders are particularly important in automation. They apply hydraulic force in both extension and retraction, making them ideal for applications that require controlled movement in two directions.

Advantages of Double Acting Hydraulic Cylinders:

- Bidirectional Force: Can push and pull with equal efficiency.

- Increased Control: More precise positioning for automated machinery.

- Faster Operation: Suitable for repetitive, high-speed applications.

- Versatility: Used in robotics, presses, industrial lifts, and more.

Common Applications in Automation:

- Conveyor systems

- Injection molding machines

- Press brakes

- Packaging machinery

Choosing the Right Hydraulic Cylinder Manufacturer

Selecting a reliable Hydraulic Cylinder Manufacturer is critical to ensure you get high-quality components that meet your automation needs.

Factors to Consider:

- Experience & Expertise – Look for manufacturers with proven experience in industrial automation solutions.

- Customization Options – Every automation system is unique. Choose a manufacturer who can provide custom cylinder sizes, materials, and pressure ratings.

- Quality Standards – Check for ISO certification and adherence to international manufacturing standards.

- Material Quality – High-grade steel and premium seals improve durability.

- After-Sales Support – Technical assistance, spare parts, and maintenance services are important for long-term performance.

Benefits of Using High-Quality Hydraulic Cylinders in Automation

- Increased Productivity: Smooth and fast operation reduces cycle times.

- Reduced Downtime: Durable construction means fewer breakdowns.

- Energy Efficiency: Hydraulic systems can be designed for minimal power wastage.

- Safety: Precision control reduces the risk of accidents.

Maintenance Tips for Hydraulic Cylinders

Even the most robust hydraulic cylinders need regular care. Here are some quick maintenance tips:

- Inspect Seals Regularly: Prevent leaks and contamination.

- Check for Misalignment: Proper installation prevents premature wear.

- Monitor Hydraulic Fluid Quality: Contaminated fluid can damage the system.

- Schedule Preventive Maintenance: Avoid costly downtime.

Future of Hydraulic Cylinders in Industrial Automation

With the rise of smart manufacturing and Industry 4.0, hydraulic cylinders are evolving. Integration with sensors and IoT devices now allows real-time monitoring of performance, predictive maintenance, and improved automation efficiency.

Conclusion

Hydraulic Cylinders, especially Double Acting Hydraulic Cylinders, are the backbone of industrial automation. They deliver unmatched power, precision, and reliability across a wide range of applications. Choosing the right Hydraulic Cylinder Manufacturer ensures you get a durable, high-performance product tailored to your specific needs.

From construction to packaging, mining to manufacturing, hydraulic cylinders keep industries moving — quite literally. As automation continues to advance, their role will only become more vital.