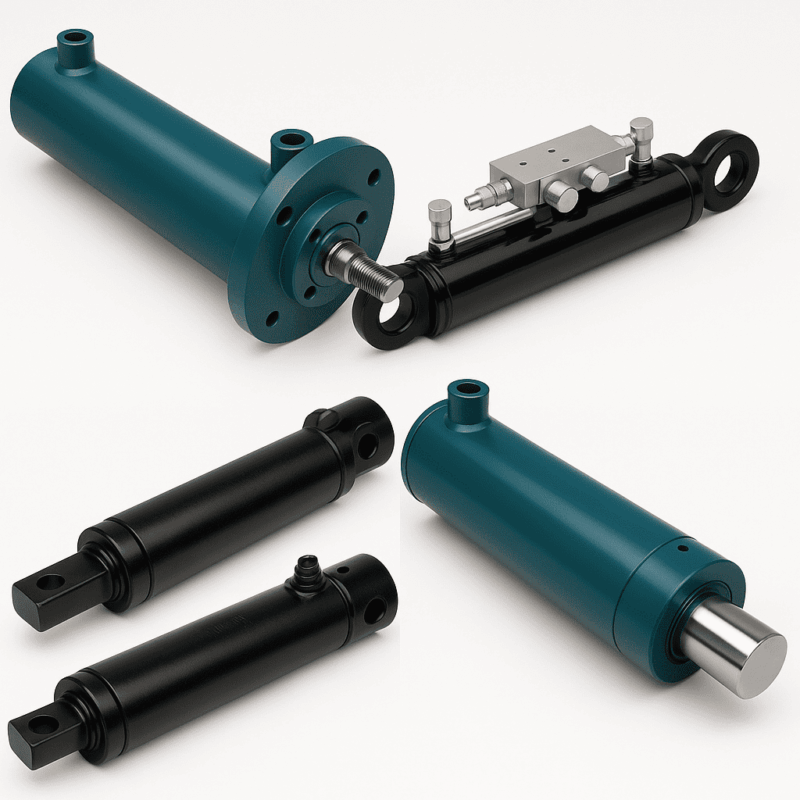

In the world of modern engineering and industrial applications, hydraulic cylinders play an essential role. These powerful mechanical actuators transform hydraulic energy into linear force, making them indispensable across construction, manufacturing, mining, agriculture, and heavy machinery industries. Behind these reliable components stands the expertise of a trusted Hydraulic Cylinder Manufacturer who combines innovation, strength, and precision to meet global demands.

As industries expand and machinery becomes more advanced, the need for high-performance hydraulic cylinders has grown significantly. This blog explores the importance of choosing the right manufacturer, the role of hydraulic cylinders in different sectors, and how a leading Hydraulic Cylinder Exporter ensures quality solutions worldwide.

The Importance of Hydraulic Cylinders in Modern Industries

Hydraulic cylinders are the workhorses of countless machines. From lifting loads in cranes to controlling the movement of excavators, they provide consistent performance and reliability. Their importance can be understood through:

- Power and Efficiency: Hydraulic cylinders deliver immense power while using relatively compact systems.

- Precision Control: They allow smooth, accurate, and adjustable motion.

- Durability: Built to handle extreme pressure, heat, and heavy-duty applications.

- Versatility: Used across industries such as agriculture, aerospace, defense, marine, and construction.

Without robust hydraulic cylinders, many critical industrial processes would fail to achieve efficiency or safety.

What Makes a High-Performance Hydraulic Cylinder Manufacturer?

Choosing the right Hydraulic Cylinder Manufacturer can make all the difference in operational efficiency. High-performance manufacturers stand out because of:

1. Engineering Excellence

Top manufacturers use advanced CAD design, modern machining technology, and strict quality checks to ensure every cylinder meets exact specifications.

2. Customization

Different industries require cylinders of varying sizes, pressure capacities, and stroke lengths. A reliable manufacturer provides custom-built hydraulic cylinders tailored to industry needs.

3. Premium Materials

High-quality steel, seals, and coatings are used to ensure durability and resistance against wear, corrosion, and extreme environments.

4. Innovative Technology

Modern manufacturers adopt smart hydraulic systems, IoT integration, and energy-efficient designs to enhance performance.

5. Compliance & Standards

A trusted manufacturer complies with international standards such as ISO, DIN, and ASTM to ensure safety, reliability, and global acceptance.

Why Partner with a Reliable Hydraulic Cylinder Exporter?

For industries operating across borders, partnering with a skilled Hydraulic Cylinder Exporter ensures seamless supply chain management. A professional exporter adds value through:

- Global Reach: Timely delivery of cylinders to industries worldwide.

- Competitive Pricing: Offering affordable solutions without compromising quality.

- Packaging & Logistics: Ensuring products arrive safely, ready for installation.

- After-Sales Support: Technical guidance and service assistance even after delivery.

By choosing a manufacturer who is also a strong exporter, businesses benefit from both world-class engineering and international trade expertise.

Applications of High-Performance Hydraulic Cylinders

Hydraulic cylinders are designed for a wide range of applications, such as:

- Construction: Excavators, bulldozers, cranes, and loaders rely on hydraulic power for lifting and movement.

- Agriculture: Tractors, harvesters, and loaders use hydraulic cylinders for enhanced productivity.

- Mining & Heavy Equipment: Cylinders withstand harsh environments and heavy loads in mining operations.

- Marine Industry: Ships and offshore equipment use hydraulic cylinders for stability and safety.

- Industrial Automation: Robotics, presses, and assembly lines depend on precision-engineered cylinders.

Each application demands strength and precision, qualities that only a reputed Hydraulic Cylinder Manufacturer can consistently deliver.

Benefits of Choosing the Right Hydraulic Cylinder Manufacturer

Working with a specialized manufacturer ensures:

- Reliability in Harsh Environments – Cylinders designed for extreme conditions maintain consistent performance.

- Reduced Downtime – Durable cylinders minimize breakdowns, keeping production on track.

- Cost-Effectiveness – High-quality designs reduce maintenance and replacement costs.

- Innovation-Driven Growth – Manufacturers continuously improve technology for better results.

Hydraulic Cylinder Manufacturing Process

To achieve high-performance, manufacturers follow a strict process:

- Design & Engineering – Creating customized solutions with CAD models.

- Material Selection – Using premium steel, alloys, and seals.

- Precision Machining – Ensuring exact dimensions for smooth performance.

- Heat Treatment & Coating – Enhancing strength and corrosion resistance.

- Assembly & Testing – Every cylinder undergoes pressure and leakage testing.

- Packaging & Export – Ensuring safe transport for international clients.

This attention to detail ensures that cylinders not only meet but exceed industry standards.

The Role of India as a Leading Hydraulic Cylinder Exporter

India has emerged as a global hub for engineering excellence, and hydraulic cylinders are no exception. Indian manufacturers are increasingly recognized for:

- Affordable yet high-quality solutions

- Strong global distribution networks

- Focus on R&D and customization

- Commitment to sustainability and eco-friendly processes

As a result, Indian companies are making their mark as trusted Hydraulic Cylinder Exporters in Asia, Europe, Africa, and beyond.

Future of Hydraulic Cylinder Manufacturing

With industries moving towards automation, robotics, and smart technologies, hydraulic cylinders are evolving too. Future trends include:

- Integration with IoT & Smart Sensors – Real-time monitoring of cylinder performance.

- Lightweight Materials – Using composites and alloys for efficiency.

- Eco-Friendly Hydraulics – Reduced leakage, recyclable materials, and energy-efficient systems.

- Global Expansion – Manufacturers focusing on wider export markets.

Forward-thinking manufacturers who adapt to these trends will lead the industry.

Conclusion

Hydraulic cylinders are the backbone of modern machinery, ensuring power, precision, and reliability across industries. Choosing the right Hydraulic Cylinder Manufacturer not only guarantees durable and efficient products but also ensures long-term savings and performance. Moreover, when the manufacturer also acts as a Hydraulic Cylinder Exporter, businesses worldwide benefit from seamless global supply, superior engineering, and trustworthy support.

If you are looking for strength, durability, and precision-engineered hydraulic cylinders, partnering with a high-performance manufacturer and exporter is the key to powering your industrial success.